7" Industrial Seamless Box Gutters on Buildings with Metal Roof

Friday, December 12, 2014 at 11:51PM

Friday, December 12, 2014 at 11:51PM First of all one of the biggest issues out there with buildings and metal roofs are that the gutters get damaged by all the avalanches off the roof once all the snow builds up and comes down all at once!

This issue of gutters getting damaged could be solved with the proper industrial gutters. Not some residential or commercial product with same grade materials as the residential, but a thick strong industrial series product.

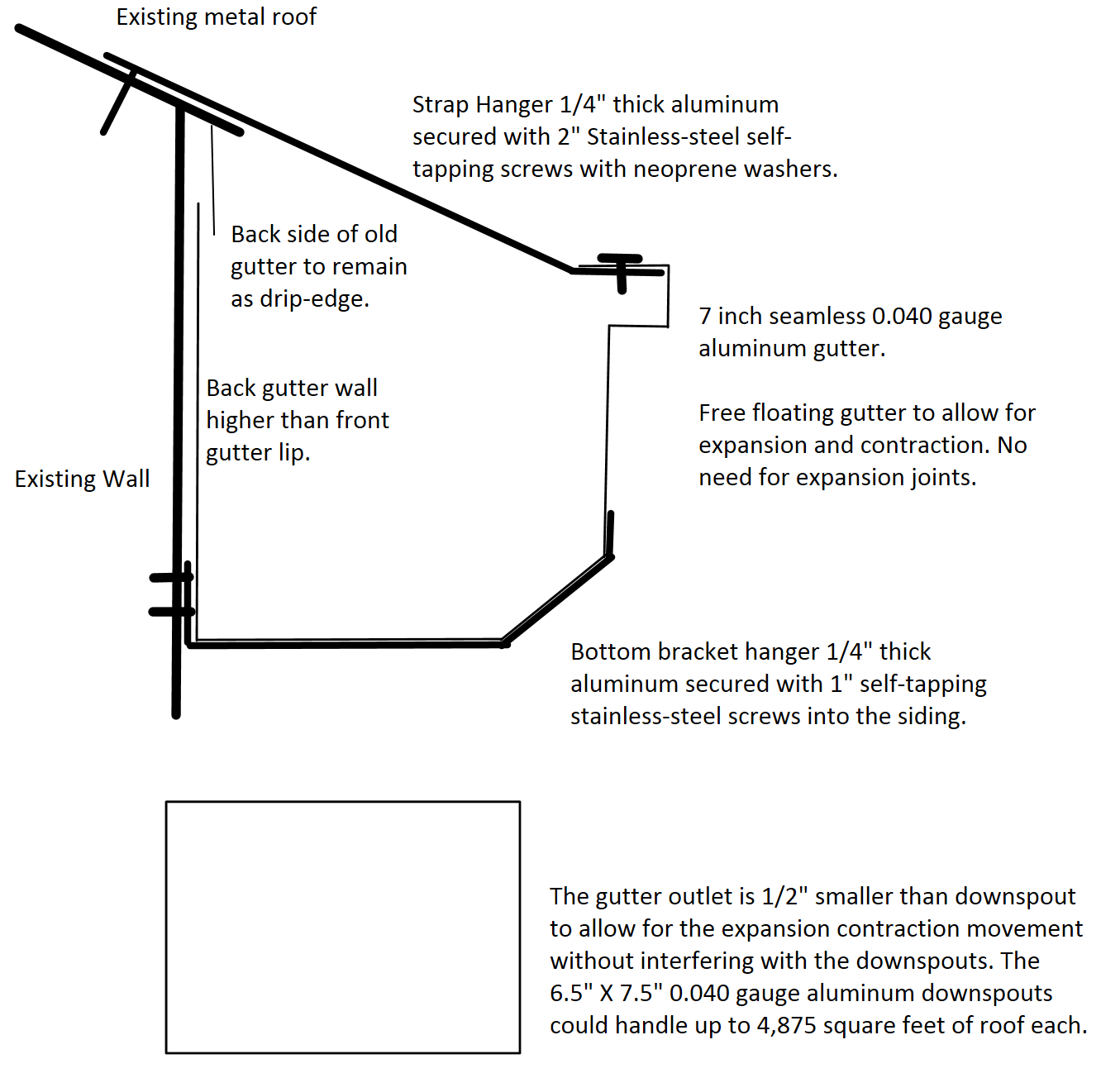

Lets discuss materials. Industrial gutters come in a thicker gauge stock, such as 0.050 gauge aluminum or more common 0.040 gauge aluminum. Could also be done in galvanized steel, or any other coil stock that could go through the industrial machine. The hangers are 2 inches wide and are 1/4" thick aluminum. Now that's not all, the frequency of the hangers could be as often as one every 12" especially for those large metal roofs. Most of the time one every 18" is all that is necessary for us to guarantee the gutters for life. How could one leave out the fasteners. That is what the whole system relies on. Without strong stainless steel fasteners the whole gutter system would be compromised. Each project calls for a specific product depending on the substrate that the fasteners are securing to. Most of the time it would be a 3" long 1/4" thick self-piercing stainless steel fastener. Two per hanger into the substrate and two 1" fasterners per hanger into the gutter.

Installation is the most important factor in guaranteeing the product for life. One of the most important factors when it comes to extremely large metal roofs is installing the gutters below the roof angle. That is so once all the snow and ice sheets start coming down they would shoot right over the gutter rather than taking the gutters down with it. Imagine the momentum behind an ice sheet that is say 200' up by say 400' wide. In case of the typical metal roofs, having the industrial seamless gutters above the roof angle is actually a better option as that could deter some of the avalanches. The industrial grade gutters could handle your typical avalanches off of a metal roof. The gutters serve the purpose of a roof snow rails or snow stops. This is of an advantage since the cost savings of installing the rails could be significant.

Pitching the gutters will determine how long the metal will last. Most don't realize that the acid in the rain and acid from the compost from all the debris in the standing water puddles will eat through the metal of the gutter and within as soon as 10 years cause pin holes through the bottom of the gutters. Also, the standing water quickly becomes ice which in turn contributes to more ice and ice dams! Therefore, it is absolutely necessary to pitch the gutters so as to prevent bellies. Keep in mind in order to pitch an industrial gutter it requires that the gutter could freely move during the installation process. That is why we discourage the use of gutters with a back flange as that makes it impossible to pitch the gutters. The purpose of the flange is to direct the water into the gutters, which could also be done with drip-edge without restricting the ability to pitch the gutters.

One thing most engineers will quickly address is the issue of expansion and contraction of a metal product such as the industrial seamless gutters. When required it is often solved per SMACNA guidelines but that restricts the placement of the downspouts and the number of downspouts as well as seams as often as one every 50 feet. What we prefer is installing a free-floating seamless industrial gutter as described in the diagram below. The industrial gutter rests on the bottom bracket, and the industrial gutter lip is secured to the roof. This way the gutter is able to expand and contract without any buckling or straining on the materials or the fasteners.

Now that we've address all things about materials and installation. Lets review the issue of water shooting off a metal roof up to 6.5" inches before it becomes vertical. After all, what is the purpose of having gutters if the gutters will not capture the water in a decent rain? Who would want to deal with water damage, erosion, and flooding especially when it comes to water off of industrial size buildings that could fill a small pond within an hour?

The way to solve the overshooting issue is over course raise the gutter above the roof angle, but with a metal roof it must be an industrial gutter system that could handle the beating from avalanches year after year. If having the gutter above the roof angle is not an option due to an extremely large metal roof or the property owner prefers that the snow would slide off the metal roof rather than be caught by the gutter, then it is adamant that the gutter is wide enough so that it is a minimum 6.5 inches past the edge of the metal roof. This is so that all the metal roof water is caught instead of overshooting the gutter.

In the next release, we will discuss industrial gutters on buildings with a flat roof such as EPDM.

To discuss your project please complete the estimate request form or call us at (866)981-5036

7" Industrial Seamless Gutters on metal roof building

7" Industrial Seamless Gutters on metal roof building

7,

7,  7in,

7in,  7inch,

7inch,  box,

box,  building,

building,  gutters,

gutters,  industrial,

industrial,  installation,

installation,  metal,

metal,  replacement,

replacement,  roof,

roof,  seamless in

seamless in  7" industriajavascript:noop()l seamless box gutters

7" industriajavascript:noop()l seamless box gutters